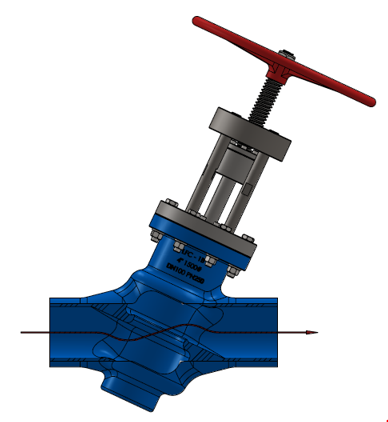

The new LFC_1B range has been designed to offer improved energy efficiency and simplicity than all its predecessors. The predecessors had an angle pattern valve body for the isolation range and a symmetrical pattern for the control valves, whereas the LFC_1B has a single type valve body, for the entire range. The LFC_1B Valve body has an angle pattern globe valve design, making it more energy efficient. due to improved Cv.

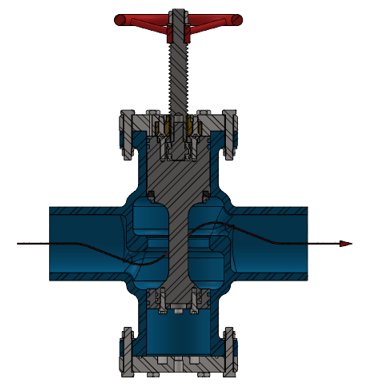

The LFC_1B range has a mechanism, in the plug, which uses the inline pressure to reduce operational torque requirements drastically. In turn, this reduction of operating force can translate into smaller actuators and gearboxes if electric actuation is required.

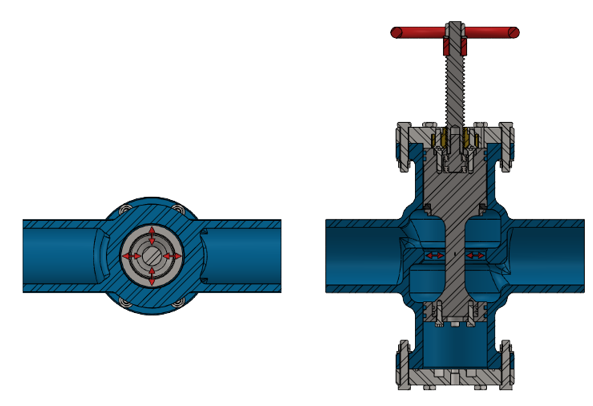

The previous designs of valves had a shuttle (plug) with a stem connecting it top & bottom actuation chambers creating a balanced or unbalanced effect, depending on the application. The shuttle stem always remained directly in the flow path and reduced the available area to accommodate flow of fluid. The reduced area created an additional pressure drop resulting in increased cavitation at low flows. The increased losses also reduced valve energy efficiency on dewatering and isolation applications. The old shuttle design also required more seals which increased the friction in the valve and reducing the line fluid activated valve sensitivity. The LFC_1B range of area ratio valves controls have less seals and friction force improving its’ accuracy and reducing its dead band zone.

Maintenance has been further simplified compared to the previous design by removal of the bottom flange from the process making the new LFC_1B design into a full top entry design.

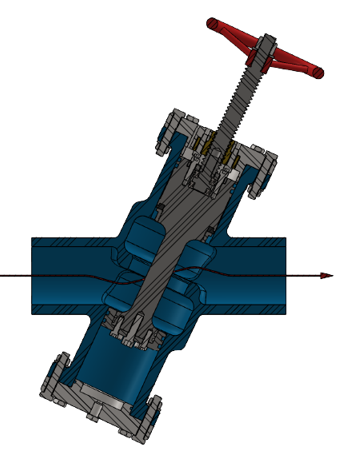

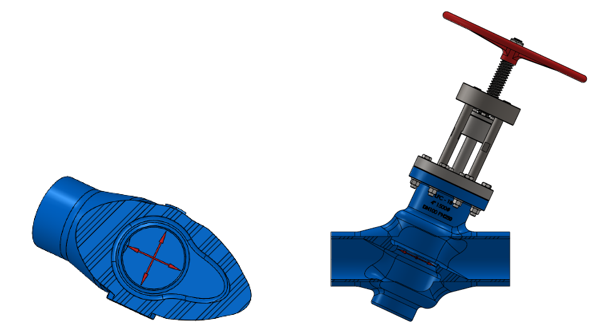

Previous angle pattern globe valve design:

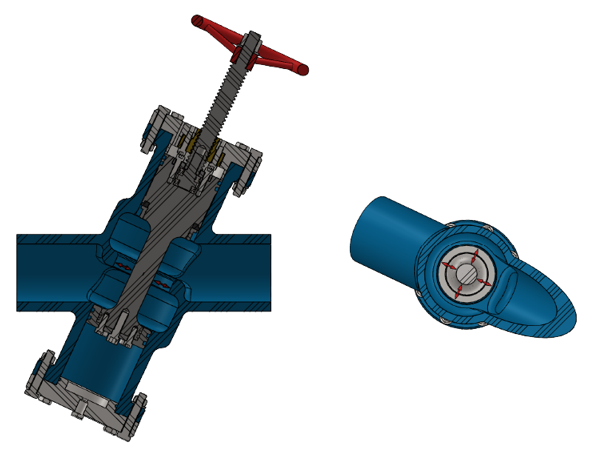

Previous Symmetrical pattern globe valve design:

New LFC_1B Angle pattern globe valve design.

The LFC_1B design concept was designed with the objective of accessing new markets which were previously inaccessible due to certain characteristics and configurations of the valve. Now we are ready to break out of the mining segment and into new markets with our fresh new range of products.

LFC_1B control valve

The LFC_1B control valve is particularly good for area ratio control which uses the upstream and downstream pressure balance to regulate valve seat position and maintain the desired discharge pressure regardless of flow.

Nitrogen charged surge and pressure relief valves offer a very accurate way of controlling the exact relief pressure for this range. Our valves can accommodate a vast range of system pressures including extremely high pressures, in this application

The LFC_1B valves are very well suited for more traditional methods of control, like pneumatic or electrical actuators due to the ultra low torque requirements and our leak tight shut off.

Our solutions for surge anticipation will become available for sale by early 2021.

LFC_1B isolation valves

The LFC_1B valve range does not require the assistance of a gearbox or bypass valve to be able to actuate the valve. The manual isolation valve can be opened & closed, under any pressure, using only its handwheel.

Due to the low torque requirements, relatively small electrical, pneumatic or oil hydraulic actuators can be used to actuate the valve where required.

The valve is excellent in applications like pump discharge control, level control and a variety of isolation applications and maintains low torque regardless of pressure differentials.

Materials

LFC_1B Valve body are manufactured from 431 S/Steel in sizes DN50 to DN100 and BS3100 Grade A3 in sizes DN150 to DN400 as standard. Special materials like 316, 304 S/Steel and other grades are also available upon special request.

The valve plugs and sleeves are normally manufactured from 304 or 431 S/Steel. Other materials for wetted components can also be requested for special applications.