HYDROMINE™ HMP_11A SANS 665 / BS 5163 PN16 Resilient Seal Gate Valves

OVERVIEW

OVERVIEW

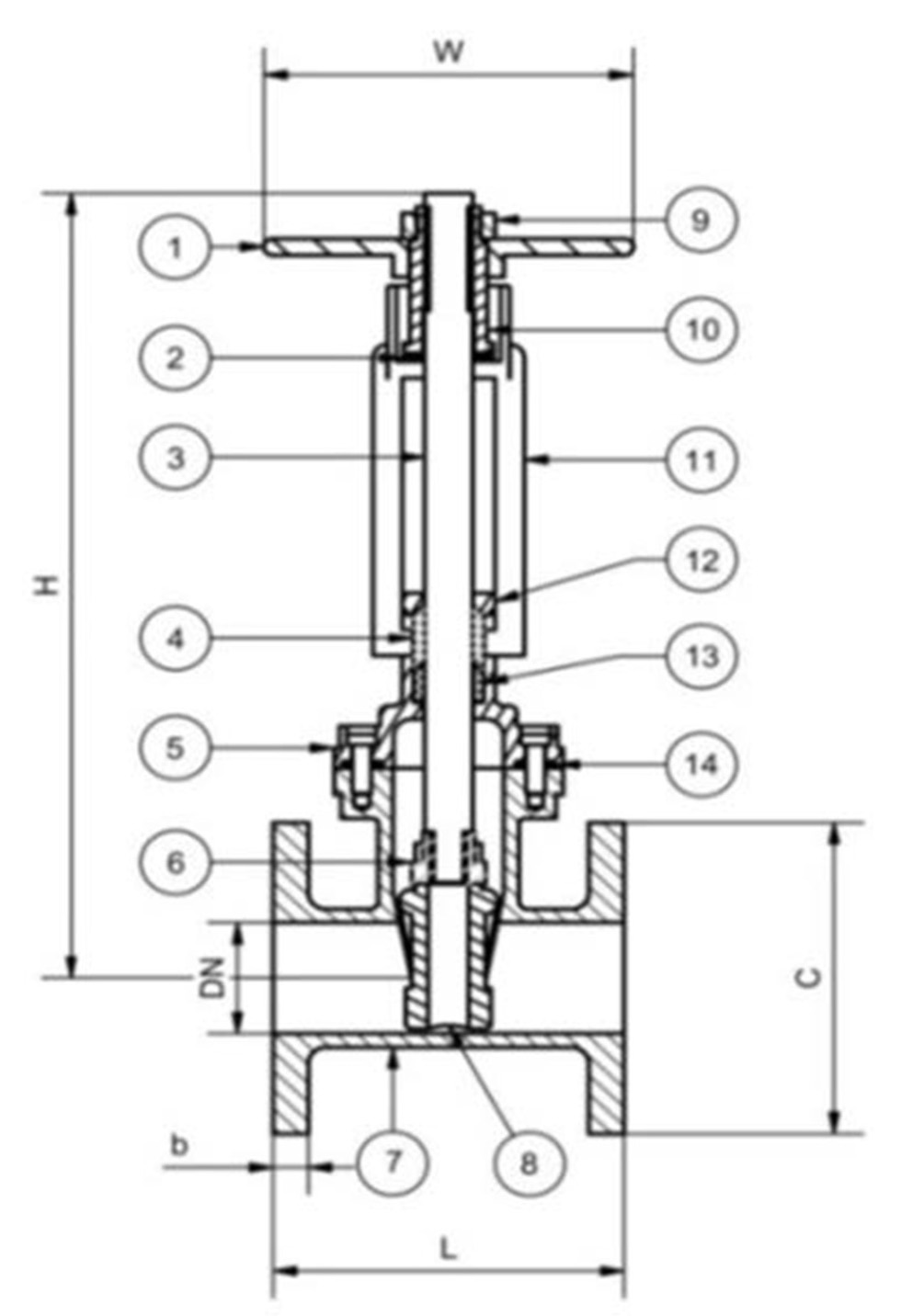

The HYDROMINE™ HMP_11A PN16 Resilient Seal Gate valve were designed for easy seating. Not a lot of force is needed for the closing of the valve, due to the EDPM (rubber) encapsulated gate. This valve is widely used in low pressure applications below 1.6 MPa such as water treatment, water distribution, mining and power generations applications. The HYDROMINE™ HMP_11A PN16 Resilient Seal Gate valve are manufactured with a bolted bonnet, flanged, face to face dimensions to SANS 665 / BS 5163 pattern, rising spindle and it's handwheel operated. The benefit of using rising spindle gate valve is that it can immediately be seen if the valve is in an open, closed or partly open position.

LOW OPERATING TORQUE

The HYDROMINE™ HMP_11A PN16 Resilient Seal Gate Valve is quite easy opening and closing under pressure with a low operating torque.

LOW MAINTENANCE REQUIREMENT

The HYDROMINE™ HMP_11A PN16 Resilient Seal Gate valve does not have a lot of parts and does not require a lot maintenance.

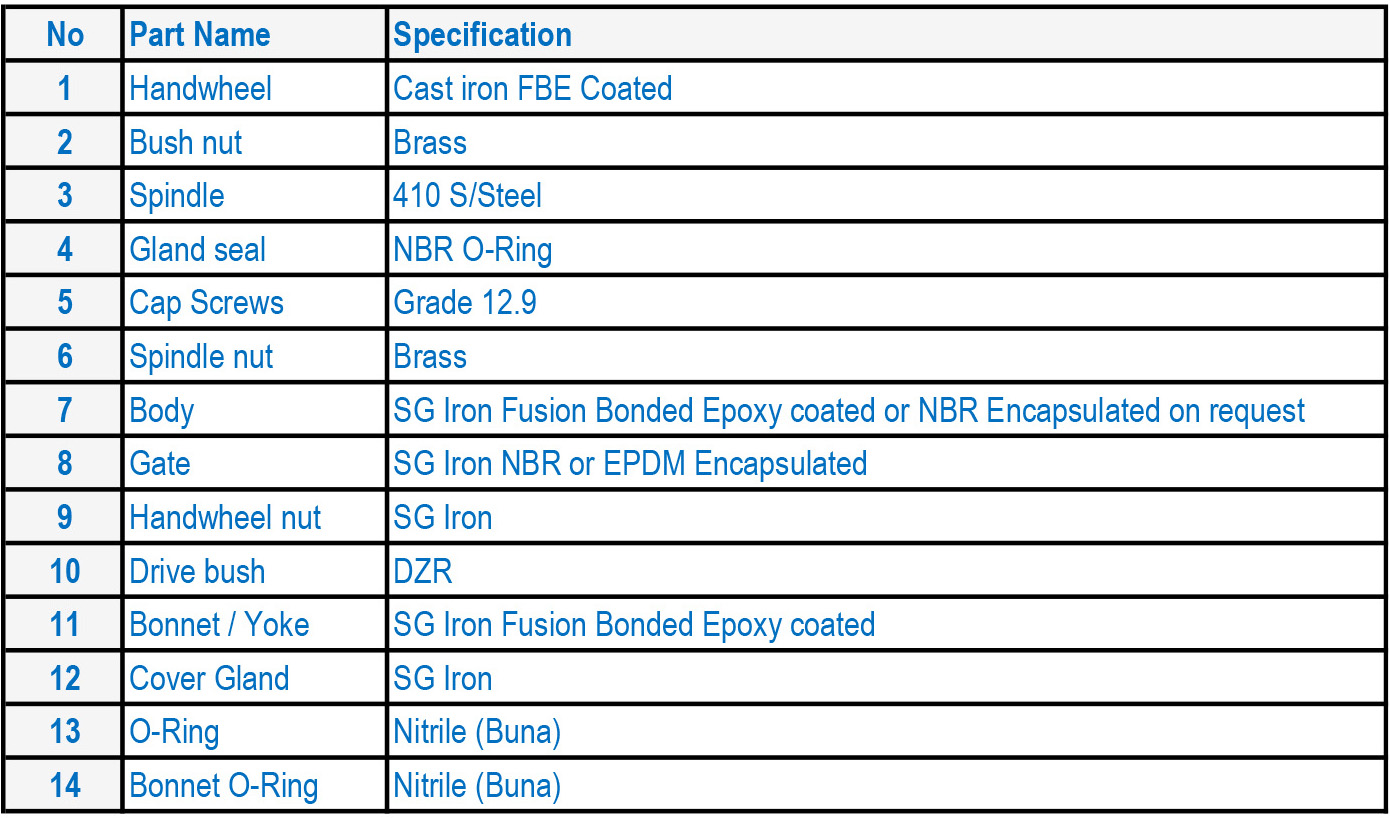

MATERIALS OF CONSTRUCTION

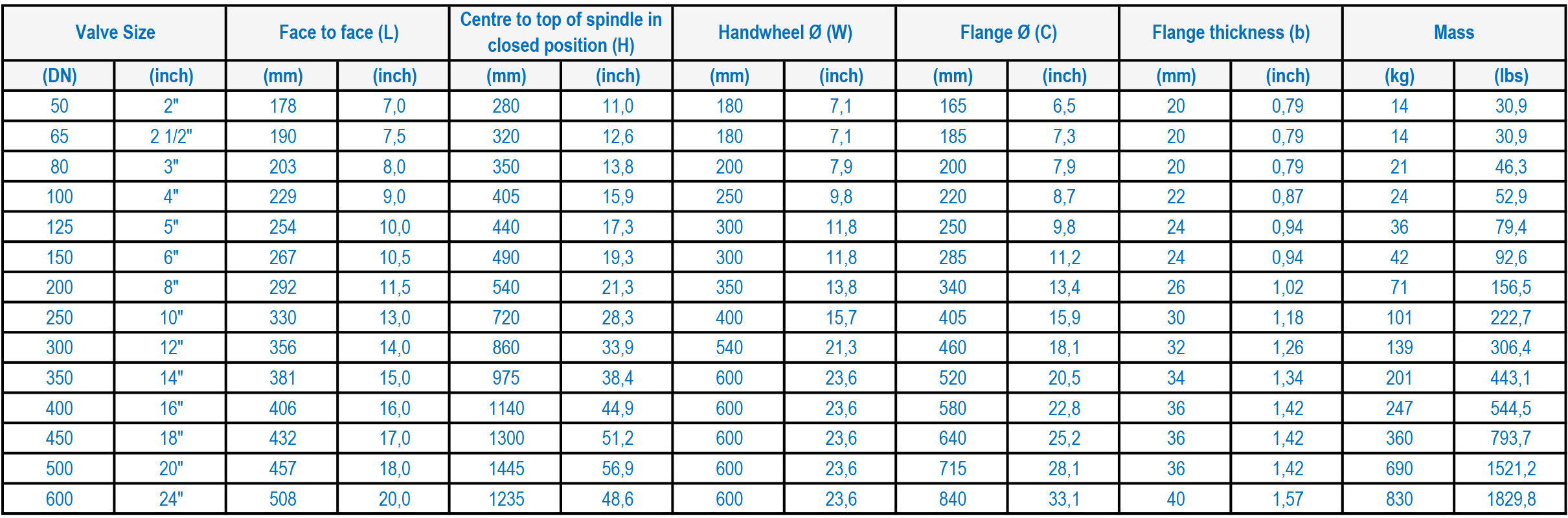

DIMENSIONS

DESIGN AND MANUFACTURING STANDARDS

The HYDROMINE™ HMP_11A PN16 Resilient Seal Gate Valve are designed in accordance with various international standards as set out below:

SANS 665

BS 5163

Flange drilling can be drilled to the following standards:

ANSI B16.1 Class 125

ANSI B16.5 Class 150

SANS 1123 T600

SANS 1123 T1000

SANS 1123 T1600

EN1092 PN10 and PN16

BS 4504 / D.I.N. T6

BS 4504 / D.I.N. T10

BS 4504 / D.I.N. T16

BS 10 / AS2129 Table D

BS 10 / AS2129 Table E

JIS B2239 5K and 10K

DOWNLOADS